A perfect projection dome begins with perfect seams

For decades, projection domes were made with overlapping or folded panels. While this solution was adequate for the low brightness levels of classic planetariums, modern projection regimes like fulldome digital and large format cinema project much more brightly, revealing visible seams with traditional seaming technologies.

Seams are the enemy of the immersive experience. With the NanoSeam™ process, Spitz changed this approach by making every panel flush with its neighbors. Instead of overlapping panels one atop another, every inch of the projection surface is completely uniform. Seams completely disappear under projection conditions.

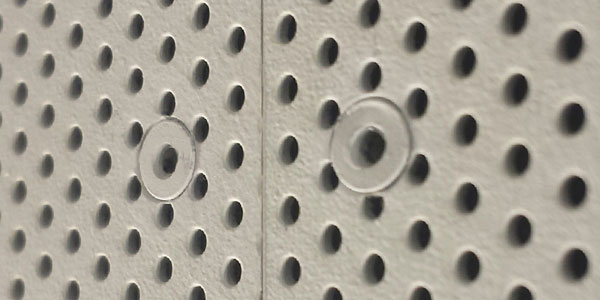

Attention to Quality is unmatched with NanoSeam. During installation, each rivet is countersunk so it’s perfectly flush with the dome surface, then custom finished to match the dome gain perfectly.

Since our first NanoSeam delivery in 2007, we’ve installed over 250 domes using this seaming process.

It’s like sitting inside a giant eggshell.

The NanoSeam dome takes our guests’ experience to another level, unlike other domes. It brings together the edges of the universe in one seamless viewing experience. We love it, so do our guests.

Contact Spitz for more information

To learn more about NanoSeam™ for your new or upgraded projection dome, contact Spitz at +1.610.459.5200.